Продукция

- Оборудование управления твердых веществ

- Triple Deck Shale Shaker

- Линейное движение Shale шейкер

- Вакуумный дегазатор

- Грязевые чище

- Desander

- Desilter

- Декантирующие центрифуги

- Sludge Vacuum Pump

- Вертикальная резка сушилка

- Сушка Shale шейкер

- Jet грязи смеситель

- Грязевые агитатор

- Центробежный насос

- Насос сдвига

- Погружной шламовый насос

- Грязи пушка

- Грязевые Газосепаратор

- Устройство зажигания огонь

- Винтовой насос

- Танк гидратации

- Грязевые танк

- Elevated Oil Tank

- Diesel Tank/Oil Tank

- Центр управления двигателя номер

- Винтовой конвейер

- Offshore Mud Skip Container

- Система управления твердых веществ

- Запасные части

- Drilling Rig

Контакт

Room 11608, Unit 1, Building C, Door of Metropolis, Tangyan South Road, New Area of High-tech District, Xi'an City, Shaanxi Province, China

Room 11608, Unit 1, Building C, Door of Metropolis, Tangyan South Road, New Area of High-tech District, Xi'an City, Shaanxi Province, China  +86-29-89305761

+86-29-89305761 +86-29-89305769

+86-29-89305769

Случаи

-

3000hp Drilling Rig Circulation System for 9000m U...

3000hp Drilling Rig Circulation System for 9000m Ultra Deep Drilling Proj...

-

2000hp Drilling Rig Mud Tank System for Saudi Arab...

2000hp Drilling Rig Mud Tank System for Saudi Arabia As earl...

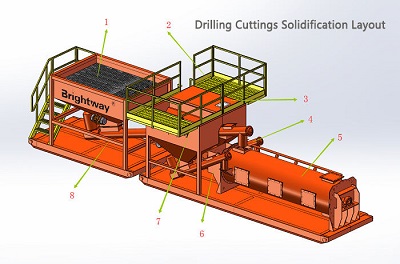

Drilling Mud Solidification System

Drilling Mud Solidification System

Drilling Mud Solidification System Structure

Drilling Mud Solidification System Layout

Drilling Mud Solidification System Working Process